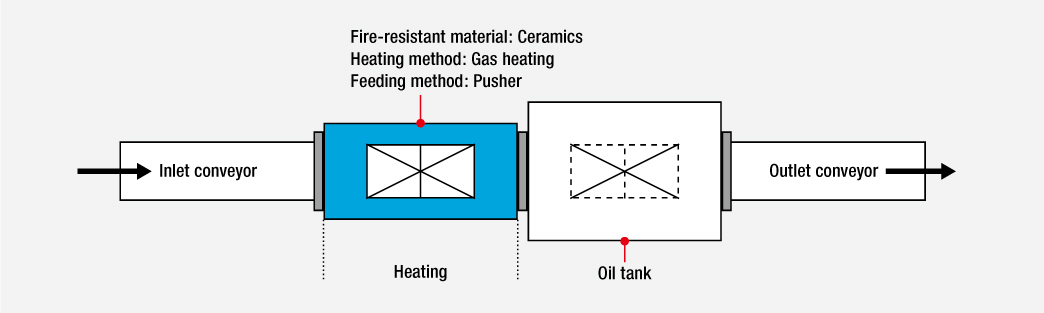

This heat treatment furnace exhibits excellent uniform heating, carburizing, and cooling performance, and is designed in consideration of quality control and maintenance. In addition to conventional brick furnaces, we have developed ceramic furnaces, electrical heating furnaces, and gas heating furnaces to meet the diverse needs of companies that specialize in heat treatment in Japan and overseas.

| Model | External dimensions (mm) | In-furnace usable dimensions (mm) | Normal temperature (°C) | Power requirements (kw)* | Capacity for one treatment process (kg) (Gross weight) |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| Overall length | Overall width | Overall height | Length | Width | Height | Heating chamber | Oil bath | |||

| TKM-40ERT | 6980 | 2550 | 3460 | 915 | 510 | 450 | 930 | 40 | 36 | 320 |

| TKM-80ERT | 8240 | 2600 | 3650 | 1220 | 660 | 600 | 930 | 80 | 48 | 550 |

| TKM-100ERT | 8810 | 2810 | 4140 | 1220 | 760 | 650 | 930 | 100 | 60 | 720 |

| TKM-120ERT | 9500 | 2810 | 4310 | 1220 | 760 | 750 | 930 | 120 | 72 | 820 |

* For oil baths, the power requirements are equivalent to the amount of power required for hot quenching processes.