Heat treatment, in simple terms, refers to a treatment that hardens and softens metals in order to change mechanical properties. Heat treatment is applied to various items and components such as vehicle undercarriages, engines and transmissions, hinge fittings of laptops, printing unit parts in printers, motors that drive the doors of automatic ticket gates in stations, contacts of mobile phones, in fact, an almost countless number of objects. Many heat-treated objects are found in your personal belongings, however, heat treatment is not something that is visible, so you will not easily notice it. Heat treatment is helpful for everyone without actually being visible.

As computerization of heat treatment equipment advances, the number of cases that require people to only rely on intuition, as used to be the case in days gone past, is falling. Nevertheless, heat treatment is not something that is visible, so it is difficult to manage. An especially high level of quality control is required to manage heat treatment processes of automotive parts, which are subject to high levels of use.

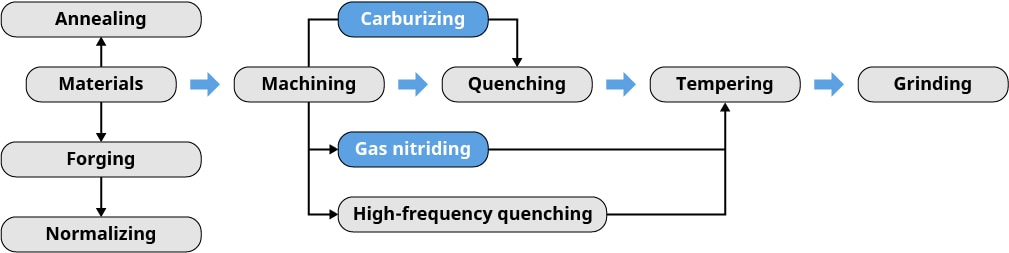

There are two types heat treatment: general heat treatment, and surface heat treatment.

| Heat Treatment | |

|---|---|

| General heat treatment (quenching, tempering, annealing, normalizing) | Surface heat treatment (carburizing, nitriding, induction) |

Metal fatigue causes cracks to appear on the surface of metal that is subject to maximum shear stress, which can lead to damage.

Therefore, it can be said that the mechanical properties of the surface layer of metal play an extremely important role.

The aim of carburizing and quenching is to increase the hardness and tensile strength by setting the surface layer to 0.7 to 0.9%C for quenching, and by transforming the material structure to martensite.

This processing results in improvement of fatigue strength and wear resistance.

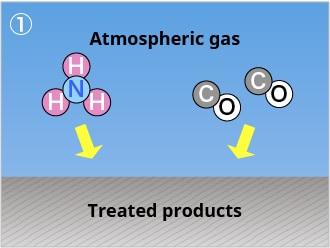

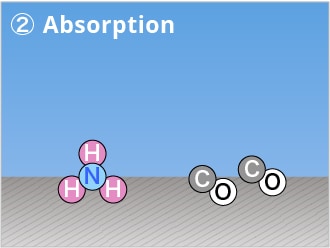

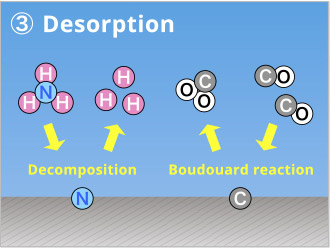

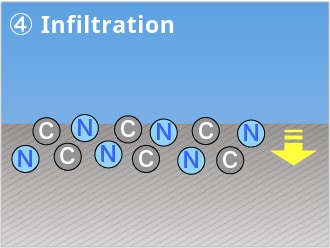

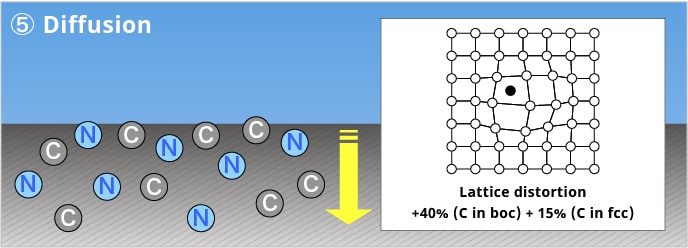

When low carbon steel transforms to an austenite structure at high temperatures and comes into contact with carburizing gas, carbon in the atmosphere enters through the steel surface, leading to internal diffusion. In this way, while the steel inside is maintained with a small amount of carbon, the surface layer can be covered with a large amount of carbon. For the carburizing treatment, many methods are currently used, beginning with solid carburizing. The gas carburizing method, which is used by our company, is the most popular method.

| Carburizing method | Carburizing reaction |

|---|---|

| Gas carburizing | Method to mix the source gas such as propane or butane with air and conduct carburizing using endothermic metamorphic gas that reacted in the gas generator as carburizing gas. |

Hardenability is enhanced (quenching distortion is reduced) by bringing nitrogen from ammonia gas (NH3) on the surface and allowing it to infiltrate inside together with carbon.

The heat treatment process applies heat to an object in order to change its physical properties. The application of heat treatment is often indicated on food products. We specialize in metallic heat treatment processes that improve the properties of steel by heating steel materials to the appropriate temperatures and adjusting the rate of cooling.

[Transmission parts]

・ Planetary gear

・ Sun gear

・ Pinion gear

・ Internal gear

・ Transmission

[Drive system parts]

・ Differential pinion gear

・ Speedometer driven gear

・ Final driven gear

・ Final drive gear

・ Hypoid gear

・ Crankshaft

・ Connecting rod

・ Intermediate shaft

・ Rocker arm

・ Pole joint

・ Wheel

・ Beam

We handle heat treatment and surface treatment for construction equipment parts and dies in addition to automotive parts.