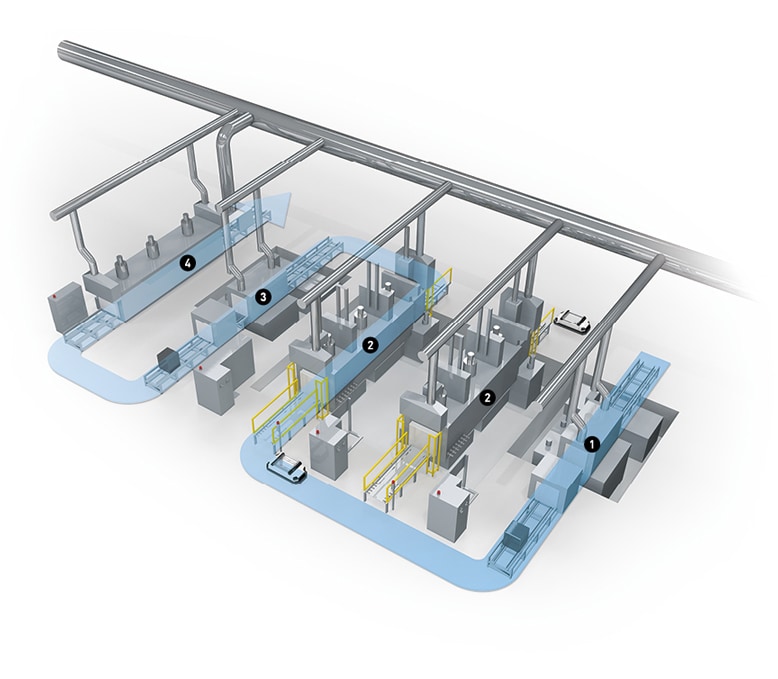

The combustion heating system is equipped with regeneration gas burners as standard equipment, which enables effective use of exhaust heat to reduce energy consumption. In addition, we conduct simulation analysis of atmospheric gases in furnaces to optimize the locations and number of gas inlets. We are determined to reduce energy usage and environmental loads.

High-functionality, fine-porous heat insulation material is used for outer walls of industrial furnaces. This minimizes heat transfer and prevents loss of heat energy (from the interior to the exterior of the furnace). In addition, the safety of the work environment is enhanced because the surface temperatures of furnace walls are reduced.

Ceramic fibers with superior heat insulation capacity and low bulk density are used for inner walls of furnaces. Applying a combination of optimal heat insulation materials to both the interior and exterior of the furnace body increases heating efficiency and significantly reduces energy costs. Using heat insulation materials with low bulk density reduces heat storage and significantly reduces the equipment setup time.

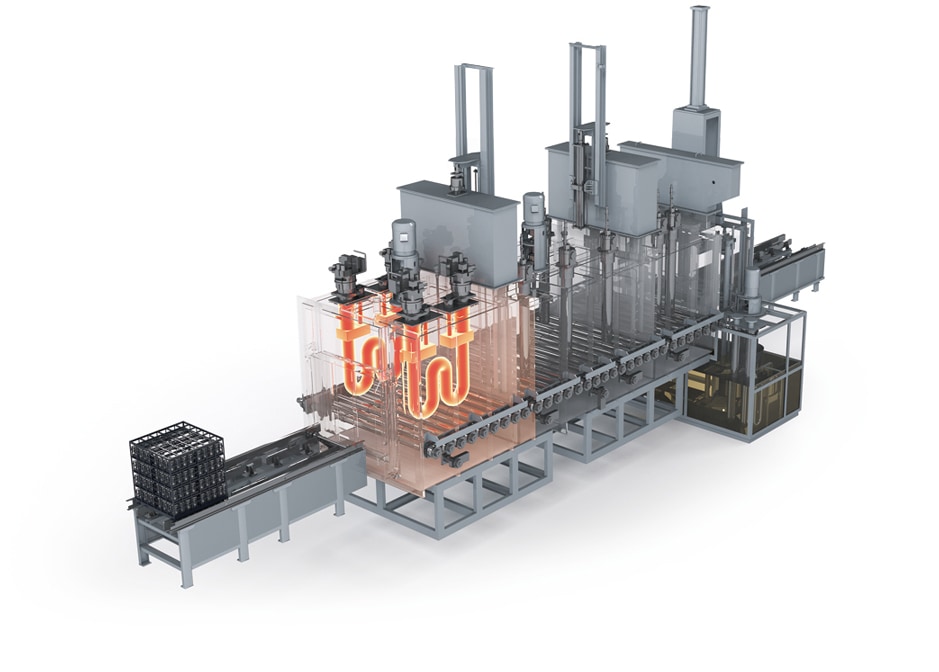

This equipment removes rust prevention and metalworking oils that have adhered to workpieces during the forging or machining processes. This operation improves the quality of the carburizing process and other heat treatment processes. In order to reduce energy usage during heat treatment processing, if requested it is possible to place a degreasing furnace that has both cleaning and preheating functions together with this equipment.

Since this furnace can be installed in an area with the same dimensions as those required for a batch type furnace, productivity can be improved and running costs reduced.

This equipment removes oil that has adhered to workpieces while they were being cooled after heat treatment processing.

This furnace reheats workpieces that have been hardened by quenching, in order to increase viscosity. A high- or low-temperature tempering furnace can be selected according to the workpiece usage requirements.