Plating Technology

We have been conducting technology development in response to changes in the market environment and customer needs. Among them, we would like to introduce our highly regarded plating technologies.

Changes in Automotive Component Requirements and Our Technological Development

| Decades | Automotive Market Environment | Customer Needs | Our Response(Details Below) |

|---|---|---|---|

| 2000s | Electrification of automobiles⇒Increase in automotive electronic components | Stable supply of high-quality plating products and cost reduction | Wide-width, multi-stripe plating |

| 2010s | Rising precious metal prices | Cost reduction (minimizing the use of precious metals) |

Spot gold plating |

| 2020s~ | Increased demand for electric vehicles (EVs, HEVs, etc.) | Increased demand for silver plating products with heat resistance and wear resistance, especially for thick plate materials used in high-current connectors | Development of Controlled Crystal Ag Plating Technology |

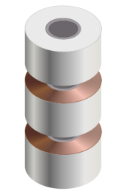

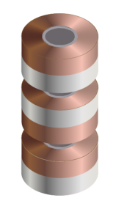

| Ag plating on thick plates for high-current connectors | Ag Plating Compatible with Thick Plates |

Our Plating Technologies

Wide-width, multi-stripe plating

By multi-stripe plating on wide-width materials, we achieve cost reduction and short lead time.

Plating processing time varies depending on the length of the material. By multi-stripe plating on wide-width materials based on the product width multiplied by the number of stripes, we can reduce plating processing time, resulting in cost reduction and shorter lead times.

In addition to overall plating multi-stripe, we also have the capability to perform multi-stripe layouts combining stripe plating, gold plating, tin plating, and other multiple plating types, allowing us to meet various customer requirements.

-

Standard Plating Processing

(Single Stripe for Product Width)Plating is performed on materials with the same width as the product. (Mainly for small quantities or prototypes) Our strength lies in our ability to handle small quantities and prototypes.

-

Wide-width, multi-stripe plating

(Multi-stripe)Plating is performed on materials wider than the product width. (Mainly for large quantities) Our strength lies in the ability to achieve cost reduction and short lead times through reduced processing time.

We can handle various plating types, including overall plating, stripe plating, and multi-color plating.

| Cost | Delivery | ||

|---|---|---|---|

| Standard Plating |

|

▲ | ▲ |

| Wide-width Plating |

|

◎ | ◎ |

Layout Examples for Wide-width Plating

Overall Plating

Slitting Example

Stripe Plating

Slitting Example

Multi-color Plating

Slitting Example

∗The above is an example. We will provide the optimal processing method based on the required quantity and plating specifications.

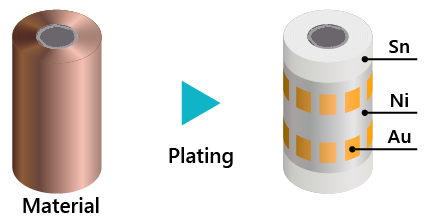

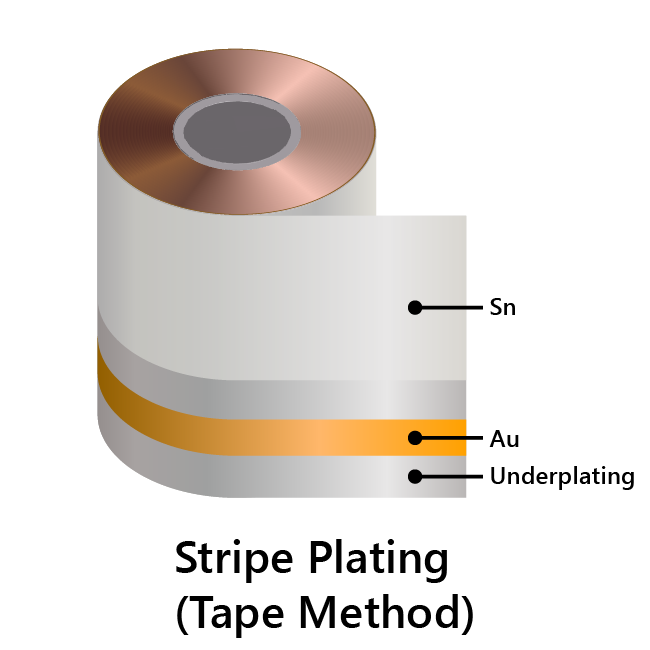

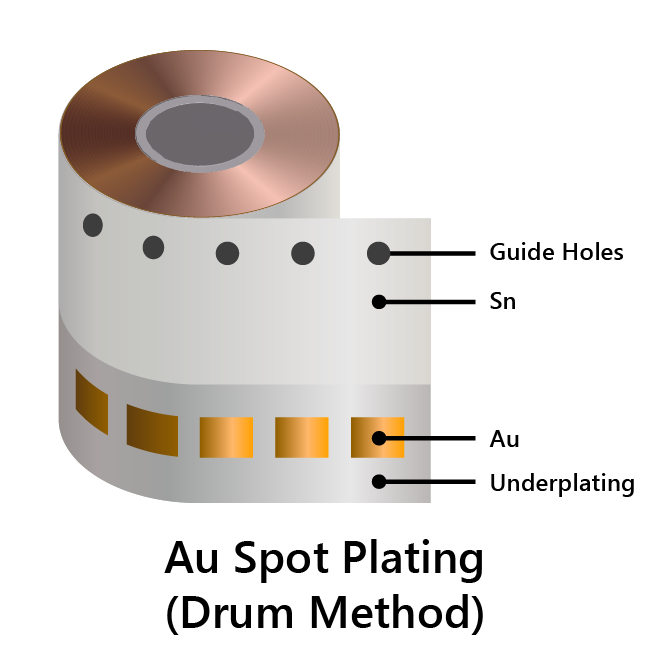

Spot Gold Plating

Significantly reduce gold usage by selectively plating only the necessary areas with gold

Conventional gold stripe plating using masking tape resulted in scrap material in areas that did not become parts during customer stamping processing.

Our spot gold plating selectively applies gold plating only to the necessary areas, eliminating gold plating on non-part areas and enabling significant cost reduction.

|

|

|

|---|---|---|

| Stripe | Method | Spot |

| Ni Underplating + Selective Au (Stripe) Au Plating Thickness ≧ 0.05μm | Specifications | Ni Underplating + Selective Au (Spot) Au Plating Thickness ≧ 0.05μm |

| 10 | Au quality ratio | 3 |

Significantly reduce gold usage and achieve cost reduction

The amount of gold reduction may vary depending on the plating layout

| Material Specifications | |

|---|---|

| Material | Copper-based materials |

| Thickness | 0.15-0.8mm |

| Width | Up to 120mm |

| Maximum Weight | 500kg |

| Spot Size Specifications(mm) | |

|---|---|

| Minimum | 1.0x1.0 |

| Maximum | 20.0x20.0 |

| Tolerance | ±0.3 |

| Plating Specifications | |

|---|---|

| Metal | Upper Limit Plating Thickness (μm) |

| Ni Underplating | 2.5 |

| Au | 1.2 |

| Cu Underplating | 1.0 |

| Sn | 3.0 |

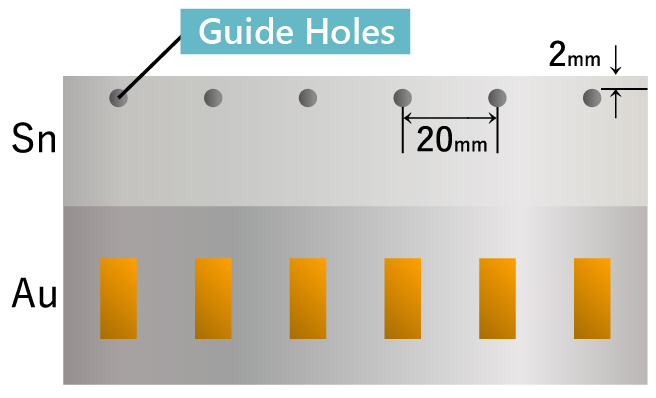

Guide Hole Processing

Spot plating requires drilling guide holes in the material for aligning the plating.

Our company can handle the guide hole processing from design to machining.

・Guide Hole Processing Example

∗May vary depending on the plating layout.

| Hole Diameter | Φ 1.5mm |

|---|---|

| Hole Pitch | 20mm |

| Hole Position | 2mm from the edge of the material |

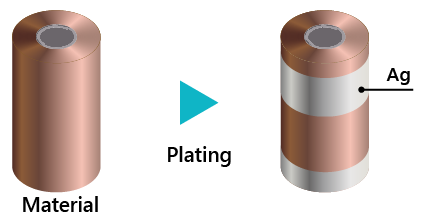

Development of Controlled Crystal Ag Plating Technology

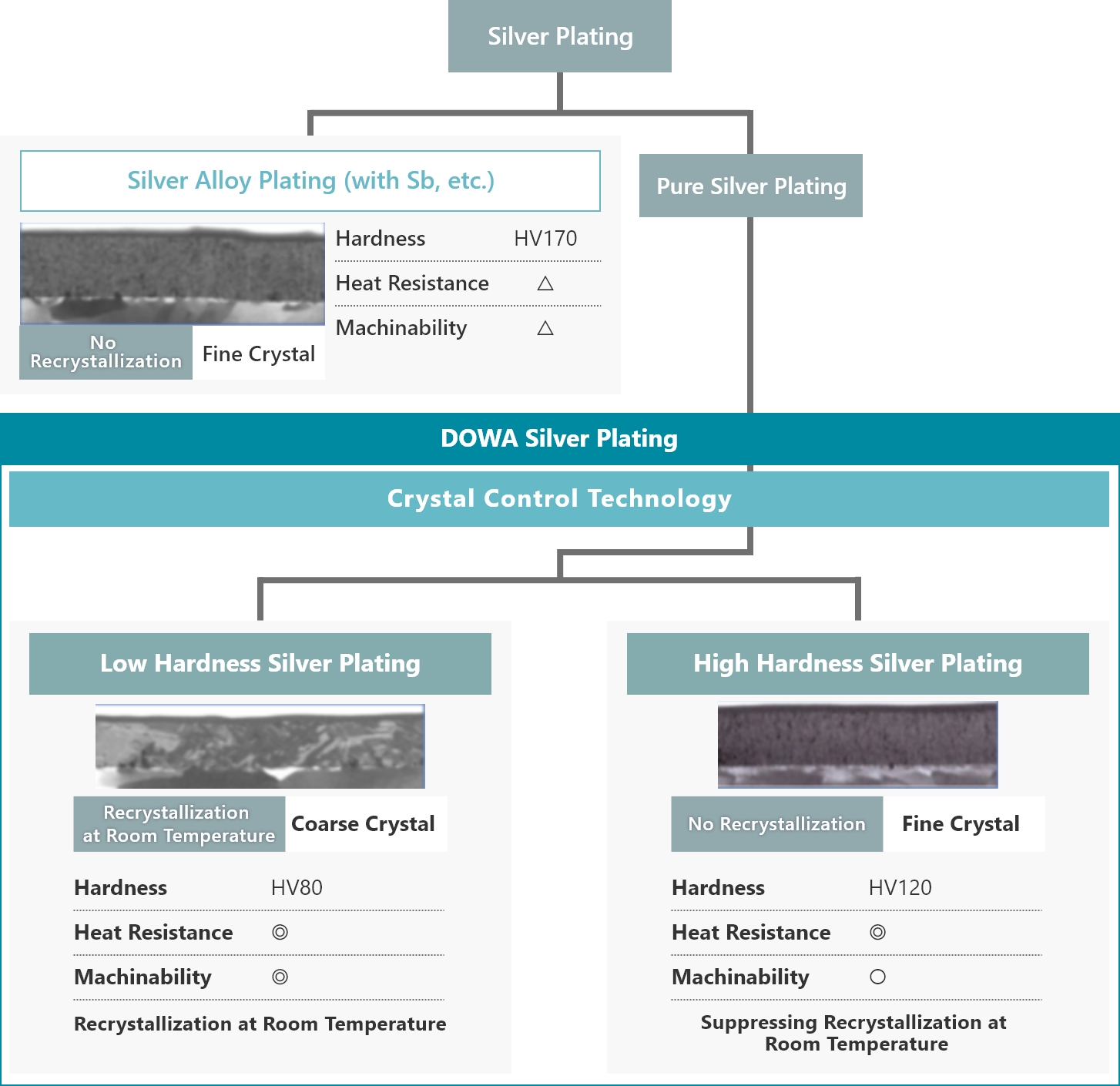

Control the grain size of silver plating to achieve differentiation between high hardness and low hardness (achieving wear resistance and heat resistance according to the application)

Silver plating is widely used not only for decorative purposes but also for a broad range of applications due to its excellent electrical properties, including electrical contacts that require conductivity.

In applications such as switches and connectors, wear due to fretting at the contact points can be inevitable, and silver alloy plating with added elements such as Sb is sometimes employed to improve wear resistance.

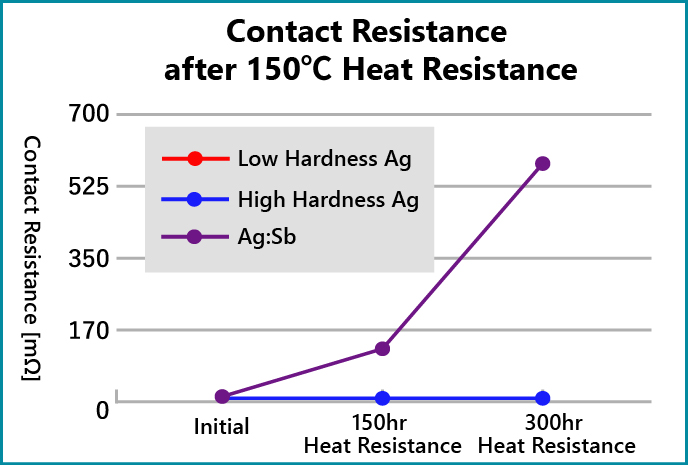

However, these added elements may oxidize at high temperatures and significantly impair the characteristics of the contact areas. Consequently, there has been a demand for silver plating that retains the electrical properties of pure silver while also offering high hardness and excellent wear resistance. In response to these needs, DOWA has developed and is providing a plating film that, while being pure silver, achieves high hardness and superior wear resistance by utilizing its proprietary crystal control technology.

Further, by intentionally reducing hardness, it is also possible to enhance heat resistance and bendability, offering a choice that can be tailored to the specific application requirements.

Types of Silver Plating

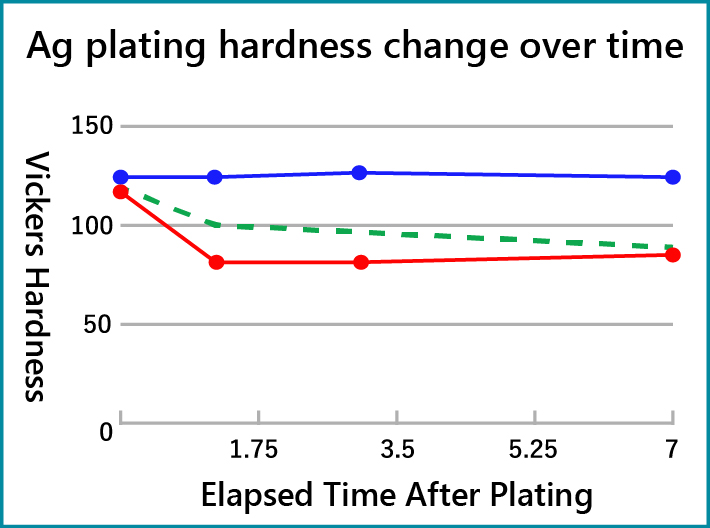

Hardness of Ag Plating

DOWA pure silver plating maintains high hardness even after plating

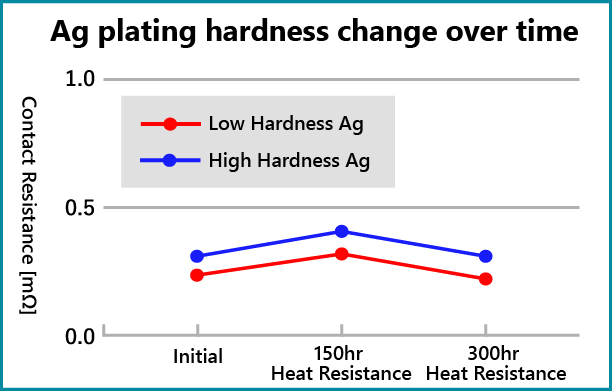

Contact Resistance

DOWA pure silver plating maintains low contact resistance even after heat resistance at 150°C

Ag Film Thickness: 3μm

Temperature: 150℃

Load: 1N

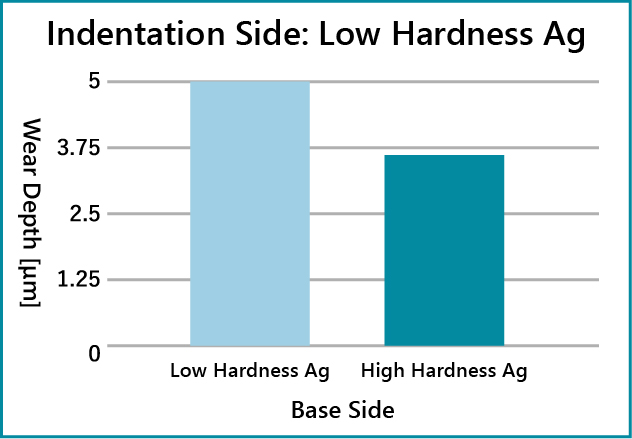

Wear Resistance

Improved wear resistance by using high hardness Ag plating

Friction Test Conditions:

| Thickness: | 0.3mmt |

|---|---|

| Ag plating Thickness: | 5μm |

| Indentation Side Radius: |

1mm

|

| Load: | 300gf |

| Fretting Speed: | 100mm/min |

| Number of Fretting: | 50 times |

| Fretting Distance: | 5mm |

| Grease: | Not used |

| n: | 3 trials per test |

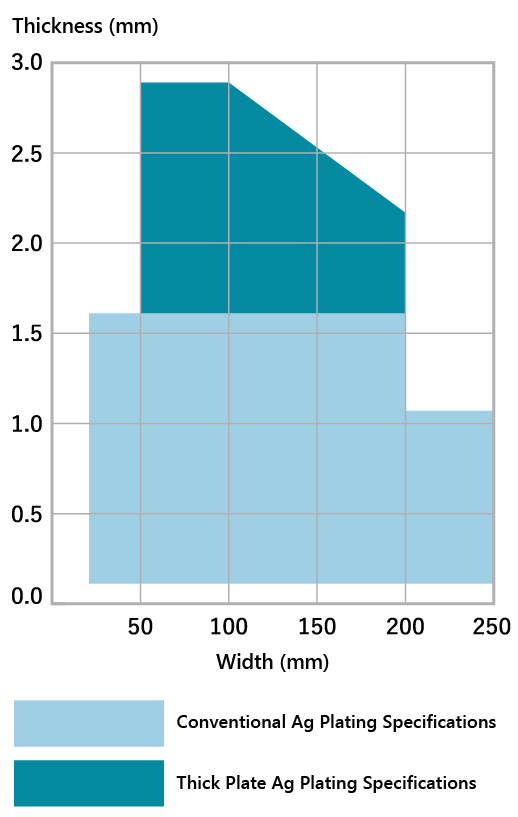

Ag Plating Compatible with Thick Plates

Ag plating on thick plates for high-current connectors

The automotive market is projected to exceed annual sales of 100 million units by 2030. Among them, electric vehicles are expected to rapidly proliferate, leading to an increase in the demand for Ag plating on thick plates due to the high-currentization of terminal components.

Plating on thick materials presents various constraints and high levels of difficulty, but DOWA has expanded its compatible specifications from the conventional upper limit of 1.5mm to 3.0mm. We can accommodate a wide range of thicknesses, from thin plates in the volume zone to thick plates used in high-current connectors.